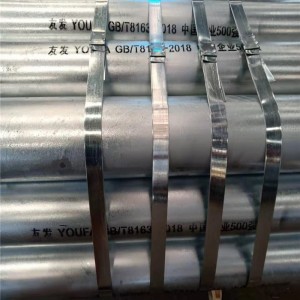

High Quality Seamless Steel Pipe

High Quality Seamless Steel Pipe

-

Tel: +8613920018539

-

Email: 2317091700@qq.com

The general production process of seamless steel pipe can be divided into cold drawing and hot rolling. The production process of cold-rolled seamless steel pipe is generally more complex than hot rolling. The pipe blank must first be subject to three roll continuous rolling, and the sizing test shall be carried out after extrusion. If the surface does not respond to the crack, the round pipe must be cut by a cutter to cut the blank with a growth of about one meter. Then enter the annealing process. The annealing shall be pickled with acid liquid. During pickling, pay attention to whether there are a large number of bubbles on the surface. If there are a large number of bubbles, it indicates that the quality of steel pipe can not meet the response standard.

The appearance of cold-rolled seamless steel pipe is shorter than that of hot-rolled seamless steel pipe. The wall thickness of cold-rolled seamless steel pipe is generally smaller than that of hot-rolled seamless steel pipe, but the surface looks brighter than that of thick wall seamless steel pipe. The surface is not too rough and the diameter is not too many burrs. The delivery status of hot-rolled seamless steel pipe is generally hot-rolled and delivered after heat treatment. After quality inspection, the hot-rolled seamless steel pipe shall be strictly manually selected by the staff. After quality inspection, the surface shall be oiled, followed by many cold drawing experiments. After hot rolling, the perforation experiment shall be carried out. If the perforation expansion is too large, it shall be straightened and corrected. After straightening, it is transmitted to the flaw detector by the conveyor for flaw detection test. Finally, it is labeled and placed in the warehouse after specification arrangement.

Seamless steel pipe has hollow section and is widely used as pipeline for conveying fluid, such as pipeline for conveying oil, natural gas, gas, water and some solid materials. Compared with solid steel such as round steel, steel pipe has the same bending and torsional strength and light weight. It is an economic section steel. It is widely used to manufacture structural parts and mechanical parts, such as oil drill pipe, automobile transmission shaft, bicycle frame and steel scaffold used in construction. Using steel pipe to manufacture ring parts can improve material utilization and simplify manufacturing processes, Save materials and processing time, such as rolling bearing ring, jack sleeve, etc. steel pipe has been widely used to manufacture. Steel pipe is also an indispensable material for all kinds of conventional weapons. Gun barrel and barrel should be made of steel pipe. Steel pipe can be divided into round pipe and special-shaped pipe according to different cross-sectional area and shape. Because the circular area is the largest under the condition of equal circumference, more fluid can be transported by circular pipe. In addition, when the ring section is subjected to internal or external radial pressure, the force is more uniform. Therefore, most steel pipes are round pipes. However, the circular pipe also has certain limitations. For example, under the condition of plane bending, the bending strength of the circular pipe is not as strong as that of the square and rectangular pipe. Square and rectangular pipes are commonly used in the framework of some agricultural machines and tools and steel and wood furniture. Special shaped steel pipes with other section shapes are also required according to different purposes.

Seamless steel pipe has hollow section and is widely used as pipeline for conveying fluid, such as pipeline for conveying oil, natural gas, gas, water and some solid materials. Compared with solid steel such as round steel, steel pipe has the same bending and torsional strength and light weight. It is an economic section steel. It is widely used to manufacture structural parts and mechanical parts, such as oil drill pipe, automobile transmission shaft, bicycle frame and steel scaffold used in construction. Using steel pipe to manufacture ring parts can improve material utilization and simplify manufacturing processes, Save materials and processing time, such as rolling bearing ring, jack sleeve, etc. steel pipe has been widely used to manufacture. Steel pipe is also an indispensable material for all kinds of conventional weapons. Gun barrel and barrel should be made of steel pipe. Steel pipe can be divided into round pipe and special-shaped pipe according to different cross-sectional area and shape. Because the circular area is the largest under the condition of equal circumference, more fluid can be transported by circular pipe. In addition, when the ring section is subjected to internal or external radial pressure, the force is more uniform. Therefore, most steel pipes are round pipes. However, the circular pipe also has certain limitations. For example, under the condition of plane bending, the bending strength of the circular pipe is not as strong as that of the square and rectangular pipe. Square and rectangular pipes are commonly used in the framework of some agricultural machines and tools and steel and wood furniture. Special shaped steel pipes with other section shapes are also required according to different purposes.

Common foreign standards: ASTM a501-98, ASTN a519-98, JIS g3441.